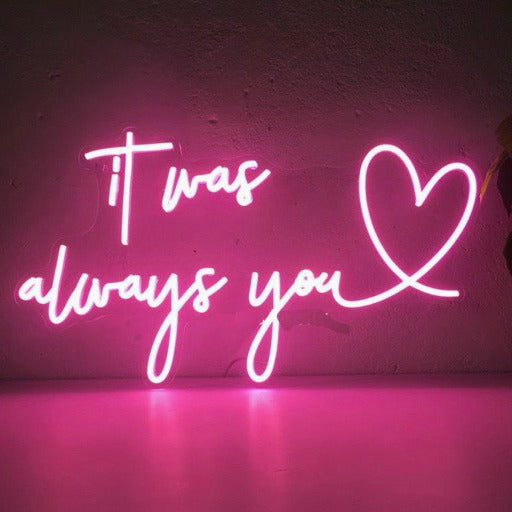

Create Your Custom Neon Sign: Explained

Jacob's Signs & Lighting, specializes in custom LED neon wall art and it's a unique eye-catching way to enhance your space with personalized designs. This detailed summary will walk you through the steps involved in creating custom LED neon wall art, from the initial design to the final product arriving at your doorstep.

-

Designing and Approving Rendered Drawing: The process begins with the client providing their concept or idea for the LED neon wall art. A skilled designer takes these ideas and creates a rendered drawing using specialized software. The designer incorporates various design elements, such as colors, shapes, and typography, to bring the concept to life. Once the rendering is complete, it is sent to the client for approval.

-

Reviewing and Finalizing the Design: The client carefully reviews the rendered drawing, ensuring that it meets their expectations and captures the desired aesthetic. Any necessary revisions or adjustments are communicated back to the designer. This iterative process continues until the client is completely satisfied with the design.

-

Material Selection and Fabrication: After the design is approved, the fabrication process begins. High-quality materials suitable for LED neon signage are selected. These materials typically include acrylic, aluminum, or other suitable substrates. The chosen materials are cut to the precise dimensions using a CNC (Computer Numerical Control) machine. The CNC machine ensures accuracy and consistency throughout the fabrication process.

-

Welding LEDs with Professional Craftsmanship: Once the materials are cut, the next step involves integrating the LED lighting into the design. Professional welders with expertise in LED neon wall art carefully position and secure the LED neon tubing onto the fabricated substrate. They use specialized tools and techniques to ensure the LEDs are aligned correctly and securely attached to the substrate. This step is crucial to achieving a high-quality finished product.

-

Quality Assurance and Testing: After the LED neon tubing is securely welded to the substrate, quality assurance checks are performed. The artwork is thoroughly inspected for any defects or imperfections. Additionally, the electrical connections and LED functionality are tested to ensure proper operation and uniform lighting. Any issues identified during this process are promptly addressed and resolved.

-

Packaging for Superior Protection: Once the LED neon wall art passes quality assurance, it is carefully packaged to ensure superior protection during shipping. The artwork is wrapped in a protective layer to prevent scratches and damage. Additional padding and cushioning materials are used to provide further protection. The package is designed to withstand the rigors of shipping and handling, minimizing the risk of any damage occurring en route.

-

Shipping and Delivery: The packaged LED neon wall art is then shipped to the client's specified address. Reputable shipping carriers are typically utilized to ensure secure and timely delivery. Throughout the shipping process, tracking information is provided so that the client can monitor the progress of their order. The package is handled with care to safeguard the artwork until it reaches the client's doorstep.

In summary, the process of creating custom LED neon wall art involves designing and approving a rendered drawing, selecting materials and fabricating them with CNC machines, welding the LED with professional craftsmanship, conducting quality assurance checks, and packaging the artwork for superior protection during shipping. Each step is meticulously executed to deliver a high-quality, personalized LED neon wall art piece that will enhance your space.